Type SPP for High-Current Applications

Aboard spacecrafts, power-generating systems rely on their cables — and, therefore, so do space missions. GORE Space Cables, Type SPP for high-current applications are highly reliable, and their robust design is small, lightweight and flexible with a tight bend radius for easy installation in tight spaces.

Nous contacter

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Improve Power Delivery Among Electrical Systems

Reliable power is essential for a successful mission. The cables that deliver the power are just as critical as the power-generating systems; without reliable cables, the power-generating systems can’t do their jobs.

GORE Space Cables, Type SPP for high-current applications provide the utmost in reliability, and their robust design and copper conductors allow for easy installation in tight spaces. Approved to ESA/SCC 3901/017 specifications and listed on the ESA QPL (Qualified Parts List), our space cables ensure that consistent power is delivered safely and reliably.

The Science Behind the Cables

The key to the outstanding performance of our space cables for high-current applications is the proprietary material used in the cable insulation: expanded polytetrafluoroethylene (ePTFE). We have created a hybrid insulation that makes the cable more flexible and easier to strip. These features make it easier to install the cables without compromising the quality of the power distribution. Additionally, the cables provide outstanding ATOX resistance and function reliably in temperatures ranging from -200°C to +200°C.

Applications

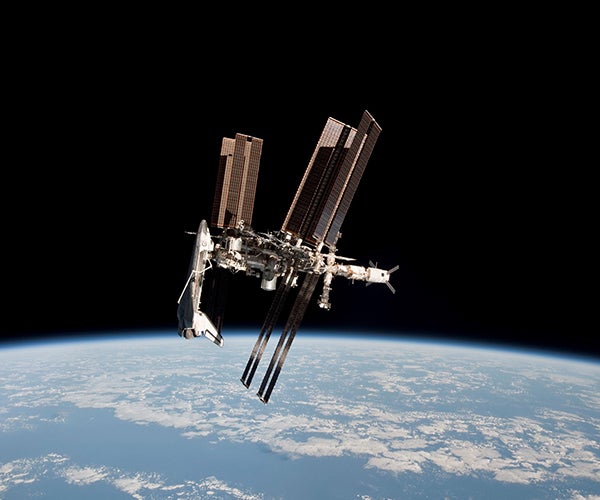

GORE Space Cables, Type SPP for high-current applications are highly reliable and easy to install in:

- manned/unmanned space missions

- high-current power supply

- spacecraft harnesses

- transfer vehicles

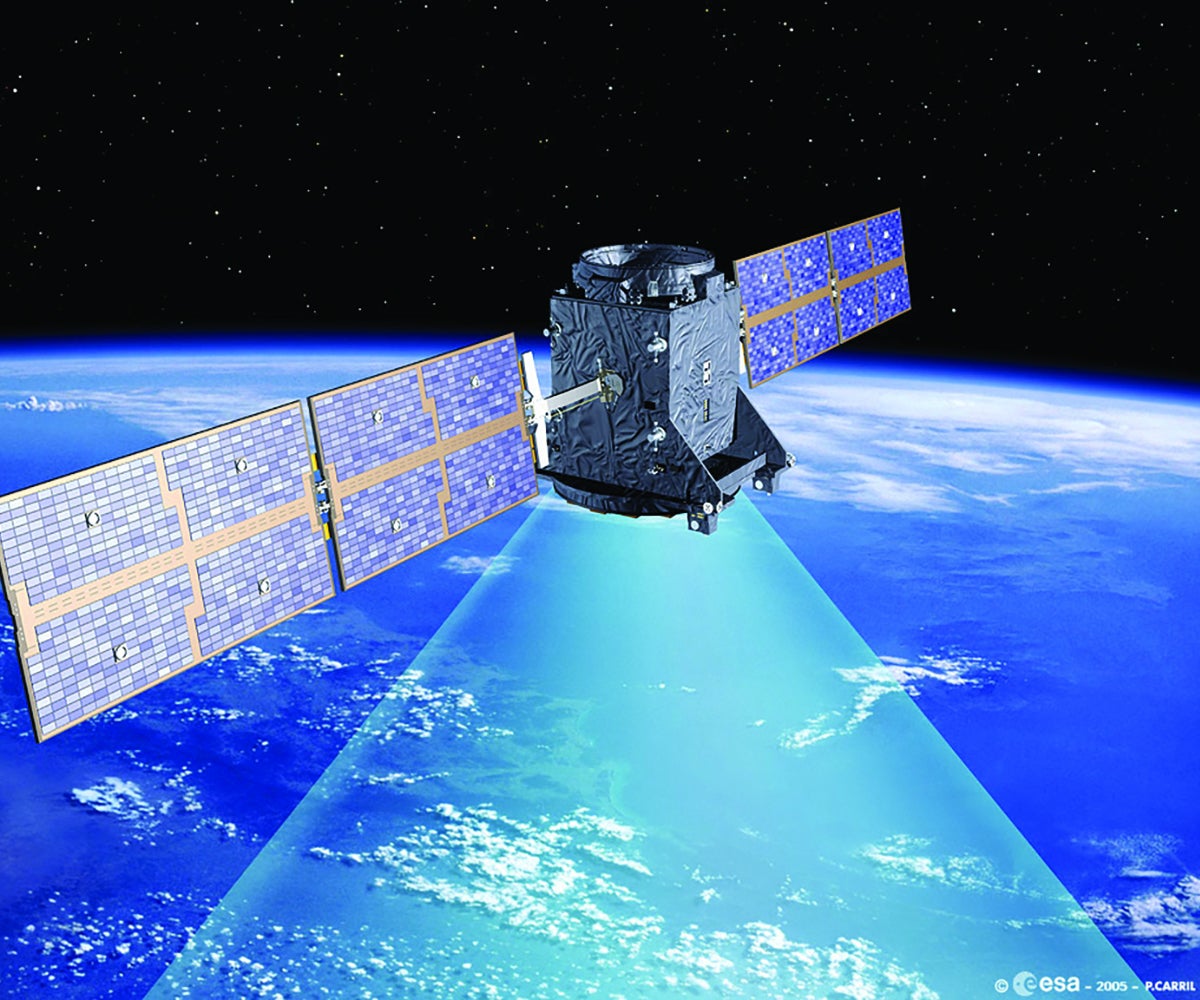

Many spacecrafts have relied upon the cables, including:

- ENVISAT satellite

- Galileo satellite

- Globalstar satellite

- INTEGRAL satellite

- XMM space observatory

For more than 25 years, we’ve provided highly reliable cable solutions for the space industry. The 100% success rate of our cables demonstrates our commitment to collaborating with customers when developing reliable and durable cables for these demanding applications.

Features & Benefits

Gore’s Type SPP space cables for high-current applications feature:

- nickel-plated copper conductors

- different gauge sizes for a variety of applications

These features benefit manufacturers and users on space flights by offering:

- outstanding performance from proprietary hybrid insulation

- excellent ATOX resistance

- improved installation with easier crimping, greater flexibility and tighter bend radius

- valued reliability delivered from an ESA-qualified and a DIN EN ISO 9001:2008-certified manufacturing facility

- qualification for ESA/SCC 3901/017

Additionally, we offer sales and technical support from Gore’s worldwide engineering team. If you have any questions about the features and benefits of our space cables, please contact us

Properties

All GORE Space Cables, Type SPP for high-current applications meet these technical specifications and are listed on the ESA QPL. See ordering information [link to Ordering] for the technical data specific to each cable.

| Property | Value |

|---|---|

| Maximum Operating Voltage | 600 V RMS |

| Conductor | Nickel-plated copper, true concentric |

| Insulation | Double layer: Expanded PTFE + polyimide |

| Conductor construction | Concentric nickel-plated copper |

| Outer Jacket | PFA |

| Temperature Range | -200°C to +200°C |

Ordering Information

GORE Space Cables, Type SPP for high-current applications are available in three variants.

When ordering, specify ESCC3901017XXB with the ‘XX’ being the appropriate variant number. For more information, please contact us.

| Variant No. | 01 | 02 | 03 |

|---|---|---|---|

| Shielded | No | No | No |

| No. of Cores | 1 | 1 | 1 |

| Wire Size (AWG) | 0 | 4 | 8 |

| No. of Strands x Diameter (mm) | 19 x 55 x 0.254 | 19 x 7 x 0.454 | 19 x 7 x 0.287 |

| Conductor Characteristics | |||

| Maximum Diameter (mm) | 10.5 | 6.5 | 4.2 |

| Nominal Section (mm2) | 53.0 | 22.0 | 8.6 |

| Maximum Resistance (Ω /km) | 0.38 | 0.91 | 2.38 |

| Shield Strand Diameter (mm) | — | — | — |

| Core Maximum Diameter (mm) | — | — | — |

| Finished Wire or Cable Characteristics | |||

| Maximum Diameter (mm) | 11.8 | 7.7 | 5.3 |

| Maximum Weight (kg/km) | 542.0 | 232.0 | 98.0 |

Resources

Learn more about GORE Space Cables, Type SPP for high-current applications in a brochure and a data sheet providing specifications, features and benefits, and typical applications.

Catalog: GORE® Space Cables for Traditional Space Applications

Product Selection Guides,

View all resources for Type SPP for High-Current Applications

Actualités récentes

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Suivre Type SPP for High-Current Applications