GORE® Microwave/RF Assemblies, 7 Series for Defense Aircraft

Gore’s durable assemblies are designed particularly to keep out water, vapor, fuel and other hazardous contaminants that can severely compromise critical mission systems. With a smaller, more flexible construction, our assemblies are proven to provide exceptional mechanical protection and electrical performance unmatched by standard rigid assemblies.

Nous contacter

United States

+1 866 271 5954

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

The aerospace environment routinely exposes microwave/RF assemblies to harsh contaminants such as fuels, oils and chemicals that can quickly degrade aircraft structures and cause assembly failure in sensitive avionics. In fact, globally more than 75% of microwave/RF assemblies are frequently replaced because of damage during installation or operation according to our independent studies and research. Costs can quickly add up with replacing assemblies, extra labor and more maintenance and downtime!

Vapor-Sealed for Durable Performance

GORE Microwave/RF Assemblies, 7 Series is engineered precisely to prevent the ingress of water vapor, fuel and other hazardous contaminants. Our award winning assemblies routinely maintain low insertion/return loss and excellent phase stability at frequencies up to 40 gigahertz (GHz).

Not only that, our robust assemblies provide outstanding shielding effectiveness against electromagnetic interference that can compromise signal integrity and reduce the quality of signal transmission. We also offer robust, low-profile connector options designed specifically to complement assembly performance, minimizing loss and reflection for optimized signal transmission.

When it comes to installation, aircraft maintainers will find it much easier to route our assemblies in confined areas because they’re smaller and more flexible with a tighter bend radius. You can be confident that our 7 Series won’t break or fail during routing like other standard assemblies that are more rigid.

The 7 Series is thoroughly tested and qualified for military airborne applications. They meet stringent mechanical/environmental requirements such as MIL-T-81490. All of this means superior performance over the aircraft’s lifetime, fewer replacements, reduced system downtime and lower total costs.

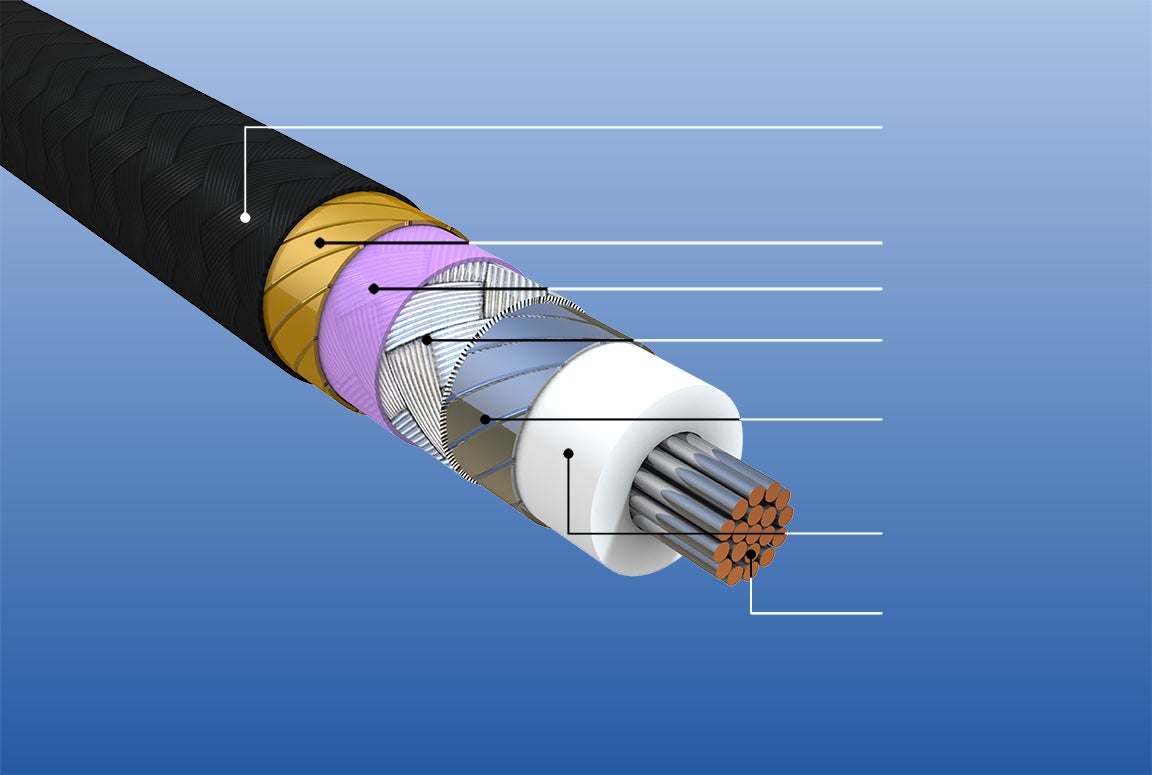

Vapor-sealed construction of GORE Mircowave/RF Assemblies, 7 Series

Applications

GORE Microwave/RF Assemblies, 7 Series is engineered to perform reliably in military airborne applications, including:

- active electronically scanned array (AESA) radar

- electronic defensive systems (signal detection, interception, identification)

- SATCOM antenna connectivity

If you have any questions or to discuss your specific application needs, please contact a Gore representative.

Benefits

GORE Microwave/RF Assemblies, 7 Series provides system architects and engineers with many benefits that improve electrical and mechanical performance such as:

- durable vapor sealing prevents ingress of water vapor and hash contaminants

- maintains low insertion/return loss with excellent phase stability up to 40 GHz

- less RF interference among electronic systems due to outstanding shielding effectiveness

- smaller diameter with greater flexibility and tighter bend radius for ease of installation

- longer system life for reduced downtime and less total costs

- increased design flexibility with a variety of robust,low-profile connector options

- meets stringent mechanical/environmental requirements such as MIL-T-81490

For more information about the benefits of our assemblies, please contact a Gore representative.

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE Microwave/RF Assemblies, 7 Series.

Download the data sheet for more technical information, including qualifications, connector options, and ordering information.

Electrical

| Electrical Property | Cable Type | ||||

|---|---|---|---|---|---|

| 7G | 75 | 7E | 7L | 7M | |

| Max Frequency (GHz) | 40.0 | 18.0 | 18.0 | 7.0 | 2.0 |

| Impedance (ohms) | 50±1 | 50±1 | 50±1 | 50±1 | 50±1 |

| Dielectric Constant | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 |

| Insertion Loss at Max Frequency (dB/m [dB/ft]) |

2.56 (0.78) |

1.05 (0.32) |

0.62 (0.19) |

0.33 (0.10) |

0.129 (0.04) |

| Velocity of Propagation | 85% | 85% | 85% | 85% | 85% |

| Time Delay (Nominal) (ns/m [ns/ft]) |

3.94 (1.2) |

3.94 (1.2) |

3.94 (1.2) |

3.94 (1.2) |

3.94 (1.2) |

| Shielding Effectiveness (dB to Max Frequency) |

>90 | >90 | >90 | >90 | >90 |

Mechanical and Environmental

| Mechanical / Environmental Property | Cable Type | ||||

|---|---|---|---|---|---|

| 7G | 75 | 7E | 7L | 7M | |

| Nominal Outer Diameter (mm [in]) |

3.80 (0.150) |

5.30 (0.210) |

8.50 (0.335) |

12.32 (0.485) |

14.35 (0.565) |

| Nominal Weight (g/m [oz/ft]) |

36.0 (0.39) |

63.0 (0.67) |

150 (1.61) |

262.0 (2.82) |

328.0 (3.52) |

| Minimum Bend Radius (mm [in]) |

19.0 (0.75) |

25.0 (1.0) |

50.0 (2.0) |

62.5 (2.5) |

80.0 (3.15) |

| Center Conductor | Solid | Solid | Solid | Stranded | Solid |

| Operating Temperature °C (°F)a |

-58 to +200 (-72 to +392) |

-58 to +200 (-72 to +392) |

-58 to +200 (-72 to +392) |

-58 to +200 (-72 to +392) |

-58 to +200 (-72 to +392) |

| Crush Resistance (kgf/cm [lb/in]) |

8.95 (50.0) |

8.95 (50.0) |

8.95 (50.0) |

8.95 (50.0) |

8.95 (50.0) |

aContact Gore for applications with an operating temperature > 175°C.

Online Tools

Easy to Use, Fast Results

Gore’s online resources are designed specifically to make it easy for you to select the right microwave/RF assembly for your specific application requirements.

NEW Microwave/RF Cable Assembly Builder allows you to design a Microwave/RF Cable Assembly with ease from your desktop, tablet or mobile phone. Whether you are working in Test & Measurement, Spaceflight, Aerospace or Defense you can design an RF cable assembly to meet your specific needs. Once you design your assemblies you’ll be able to download custom datasheets for your builds within minutes, and you can also submit the builds for a quote. A Gore specialist will then review your designs and application requirements.

Microwave/RF Cable Assembly Calculator allows you to calculate insertion loss, VSWR and other parameters of Gore’s assemblies for different cable types. Select and compare up to 3 cables at a time.

If you have questions about our assemblies and want to discuss your specific application needs, please contact a Gore representative.

Resources

Data Sheet: GORE® Microwave/RF Assemblies, 7 Series for Defense Aircraft

Data Sheets, 365.02 KB

View all resources for Microwave / RF Assemblies, 7 Series for Military Aircraft

Actualités récentes

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Produits associés

Cables & Cable Assemblies

- GORE-FLIGHT® Microwave Assemblies for Defense Aircraft

- Microwave/RF Assemblies for Defense Aircraft

- Ethernet Cables for Defense Air & Land

- Shielded Twisted Pair Cables for Defense Air & Land

- Fiber Optic Cables for Defense Air & Land

- USB Cables for Defense Aircraft

- HDMI Cables for Defense Aircraft

- Quad Cables for Defense Aircraft

- Fibre Channel Cables for Defense Aircraft

- CAN Bus Cables for Defense Aircraft

- DVI Cables (Digital Only) for Defense Aircraft

- FireWire® Cables for Defense Aircraft

- MIL-STD-1760 Assemblies for Defense Aircraft

- Hook-up Wire for Defense Aircraft

Sealants

Suivre GORE® Microwave/RF Assemblies, 7 Series for Defense Aircraft