GORE® Space Cables, SpaceWire for NewSpace

When vital systems demand constant data transmission, Gore’s qualified cables deliver unfailing bi-directional signals at high data rates in harsh launch and orbit environments. We combine high-strength, lightweight materials with LVDS technology and standard hardware protocols to meet time-critical program schedules and tight budgets.

Nous contacter

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

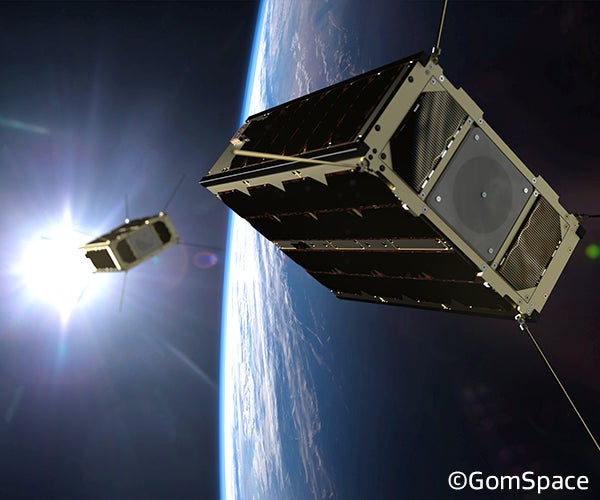

AFFORDABLE SOLUTION DELIVERED FAST

Data transmission is essential to the success of every mission that launches satellites into orbit. If data can’t be transmitted, we can’t access information online and effectively monitor the earth. The growing NewSpace sector also wants low-weight cables that fit in smaller launch vehicles and satellites, plus cost less for use in frequent missions.

Gore can meet these challenges. By combining our extensive materials expertise with decades of proven traditional spaceflight heritage, we offer a reliable, affordable high data rate solution delivered quickly for NewSpace applications.

CONSTANT HIGH DATA RATE TRANSFER

GORE Space Cables, SpaceWire are proven to maintain constant bi-directional, high data rate transmission up to 400 Mbps with minimal crosstalk, low insertion loss and low skew. They use a serial, point-to-point dataline with reliable LVDS (Low Voltage Differential Signals). We support LVDS by using uniquely engineered materials that allow data to pass through the cable without significant signal loss. By combining this LVDS technology with standard hardware protocols, our cables offer a simple cable management solution without the need for customized program designs.

Our unique materials are also high strength, so these cables can easily tolerate the most severe conditions. For instance, extreme temperatures, shock and vibration during launch sequences. Or radiation, outgassing and intense temperature changes during satellite missions. Plus, our materials have the added benefit of being low weight, so they can be easily integrated into smaller launch vehicles and satellites where space is a premium.

We can also manufacture our cables quickly at a price you can afford to meet your time-critical program schedules and tight budgets. GORE Space Cables, SpaceWire meet the challenges of NewSpace by providing all-around durable protection and reliable performance for the duration of the mission.

Applications

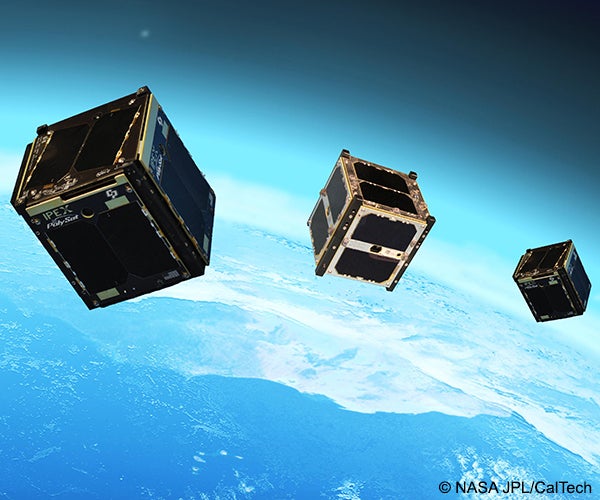

PROVEN PERFORMANCE ACROSS NEWSPACE APPLICATIONS

With reliable LVDS technology at high data rates, GORE Space Cables, SpaceWire deliver unfailing signals in a variety of low Earth orbit (LEO) and medium Earth orbit (MEO) applications, including:

- command and data handling (C&DH)

- high-resolution cameras

- radar sensor equipment

- sensor, mass memory unit and telemetry subsystem interconnections

If you have any questions or to discuss your specific application needs, contact a Gore representative today.

Features & Benefits

GORE Space Cables, SpaceWire are engineered with unique features that make them more durable against challenging environmental factors and onboard conditions, including:

- chemically inert, temperature- and abrasion-resistant materials

- low outgassing and radiation-resistant materials

- low-weight design with reduced diameters

Our cables provide system architects and engineers with many benefits that improve electrical, mechanical and environmental performance such as:

- constant bi-directional high data rate transfer up to 400 Mbps

- proven minimal crosstalk, low loss and low skew

- high-strength build tolerates extreme temps, shock, vibration, more

- slim, lightweight size helps meet challenging mass budgets and tight installation paths

- affordable solution delivered fast to meet demanding program schedules and frequent launch capabilities

- low-risk product qualified to ESA Class 2 and NASA Level 2

- selected complimentary samples with short lead times for prototyping and evaluation

- leverage proven performance with 100% failure-free flight record in hundreds of traditional spaceflight programs

For more information about the features and benefits of our cables, contact a Gore representative today.

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE Space Cables, SpaceWire for NewSpace applications.

| Electrical Property | Value |

|---|---|

| Data Rate Mbps | Up to 400 |

| Standard Impedance Ohms | 100 + /- 6 |

| Maximum Operating Voltage Vrms | 200 |

| Time Delay ns/m (ns/ft) Pair Conductor Difference (Pair) Conductor Difference (Pair-to-Pair) |

4.30 (1.31) 0.08 (0.24) 0.13 (0.04) |

| Capacitance pF/m (pF/ft) Conductor-to-Conductor Conductor-to-Shield |

50.0 (15.2) 90.0 (27.4) |

| Skew Within Pair ps/m (ps/ft) | ≤ 150.0 (46.0) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor/Shield |

1400 |

| Mechanical / Environmental Property | Value |

|---|---|

| Jacket Material | PFA |

| Jacket Color | Yellow |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color-Coding | Blue/White, Brown/White, Green/White, Red/White |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -200 to +180 |

| Radiation Resistance MRad | 10+ |

| Vacuum Stability % (ASTM 595; ECSS-Q-70-02) Volatile Condensable Mass (VCM) Total Mass Loss (TML) |

< 0.1 < 1.0 |

Qualifications

With a thorough understanding of products operating in space, customers’ needs and appropriately scoped NewSpace test procedures, GORE Space Cables, SpaceWire are tested and qualified in adherence to strict standards, including:

- ESA ECSS-Q-ST-60-13C, Annex G Class 2: Space Product Assurance — Commercial Electrical, Electronic and Electromechanical (EEE) Components

- NASA EEE-INST-002 Level 2: Instructions for EEE Parts Selection, Screening, Qualification, and Derating

For more information about the qualifications of our cables, contact a Gore representative today.

More Information

LEARN MORE ABOUT GORE SPACE CABLES, SPACEWIRE OR ORDER NOW

For vital onboard systems that demand constant high speed data transmission, our SpaceWire cables offer reliable, low-risk performance in smaller launch vehicles and mini satellites. Qualified complimentary samples are available for this product within 48 hours in the U.S. for prototyping and evaluation.

Find out about in-stock availability when you’re ready to order by getting in touch with our authorized U.S. distributor. Or, connect with a Gore NewSpace specialist today for more information and to discuss your specific application needs and requirements.

Resources

Brochure: GORE® High Speed Data Cables for NewSpace

Brochures, 1.91 MB

View all resources for GORE Space Cables, SpaceWire for NewSpace

Actualités récentes

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Produits associés

Cables & Cable Assemblies

Suivre GORE® Space Cables, SpaceWire for NewSpace