Présentation

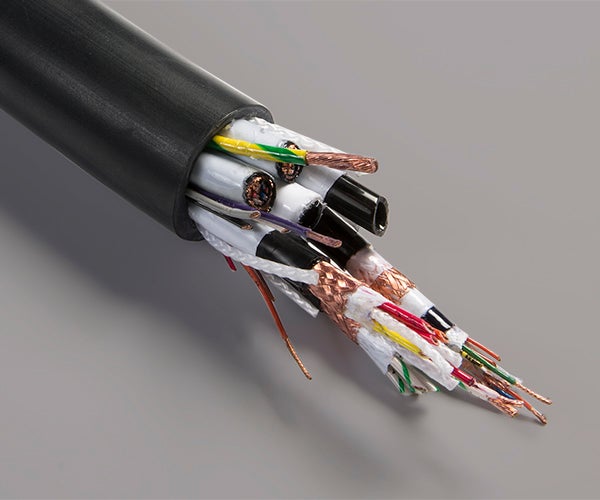

Les câbles peuvent être des composants essentiels, voire même incontournables des systèmes électroniques. La défaillance d'un câble peut provoquer une panne de tout le système.

Les câbles sont soumis à quatre facteurs déterminants pour leur performance : mécanique, électrique, environnemental et spécifique à l'application. Les fabricants doivent donc s'assurer de leur résistance à des conditions difficiles ainsi que de la fiabilité de leurs performances tout au long de la durée de vie du système. Qu'ils soient utilisés dans des systèmes terrestres, souterrains, dans l'océan, l'air ou l'espace, les câbles doivent être conçus pour durer.

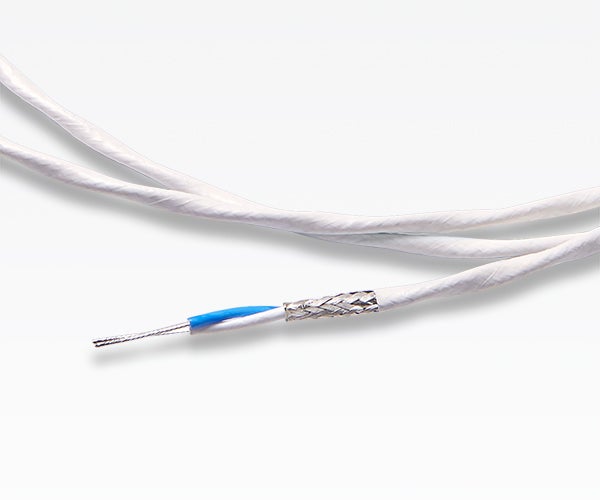

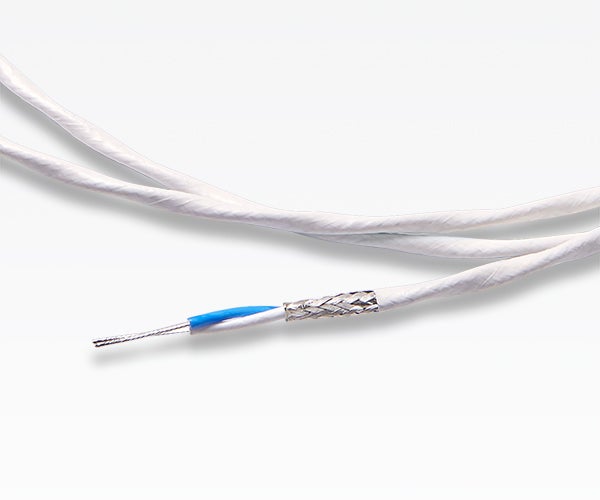

Les câbles et câbles assemblés de Gore bénéficient d'un design durable, compact et souple qui contribue à assurer la sécurité et la réussite de chaque vol, mission, exploration, extraction et production.

Les applications ont évolué, tout comme nos compétences en ingénierie. En 1958, Gore a commencé à réaliser des prototypes de câbles isolés en fluorocarbone et de câbles plats pour les véhicules spatiaux, les équipements de contrôle au sol et les avions militaires. Aujourd'hui, nous associons notre grande expertise en technologie basée sur les matériaux polymères à notre excellente maîtrise de l'intégrité des signaux pour fournir des solutions haute performance dédiées aux avions commerciaux, au matériel de forage de puits de pétrole, aux semi-conducteurs et bien plus encore.

Industrie aérospatiale

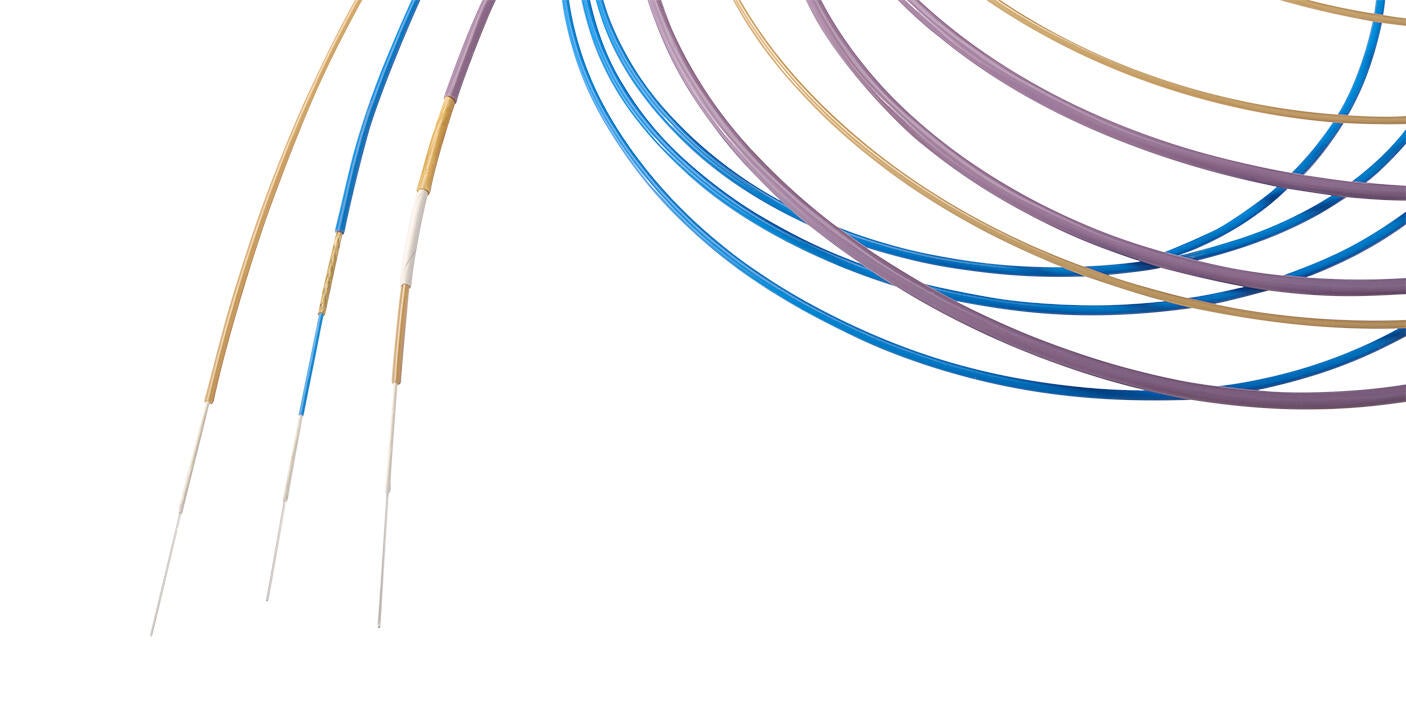

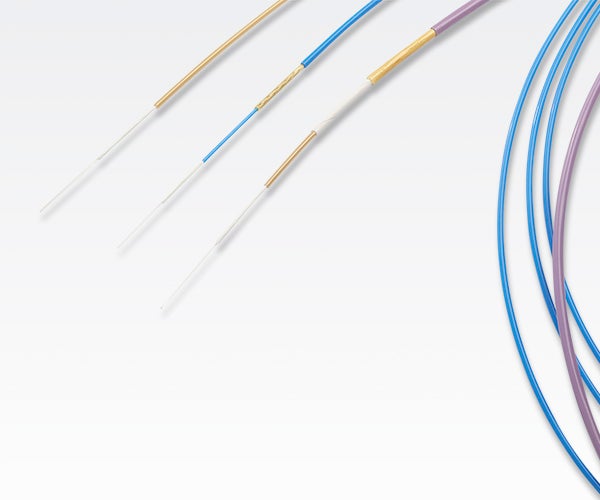

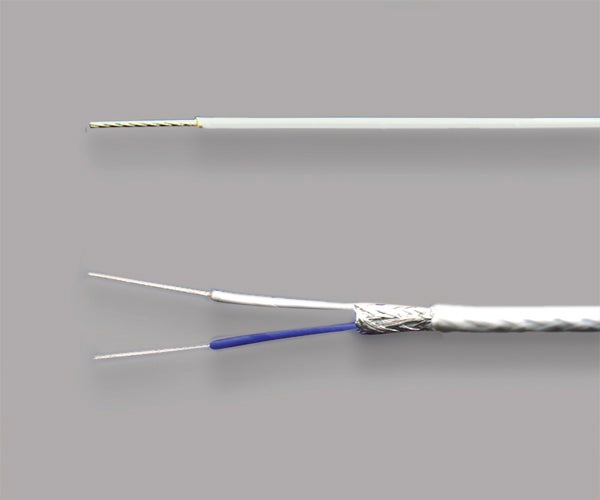

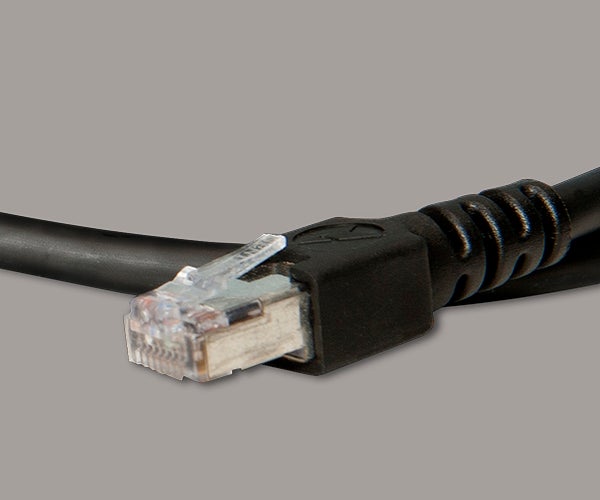

Qu'il s'agisse d'alimenter les stations spatiales en énergie ou de transmettre des données essentielles aux aéronefs et engins spatiaux, les produits Gore ont été conçus pour offrir un fonctionnement sans faille quel que soit l'environnement. En associant nos matériaux innovants à notre expertise en matière de diélectrique, nous offrons une vaste gamme de solutions en cuivre et fibre de faible encombrement qui est capable de résister à de nombreux défis, notamment les chocs et vibrations durant le vol, les températures spatiales allant de -200 °C à +200 °C et la courbure pendant l'installation.

Nos solutions assurent un acheminement rapide et fiable de l'alimentation électrique et des signaux avec de faibles pertes sur la durée de vie totale du système. Les produits éprouvés, comme les câbles Ethernet pour l'aérospatial GORE® Aerospace Ethernet Cables et les câbles micro-ondes assemblés GORE-FLIGHT™ Microwave Assemblies, continuent à remporter des récompenses en matière d'innovation produit et système.

Systèmes terrestres

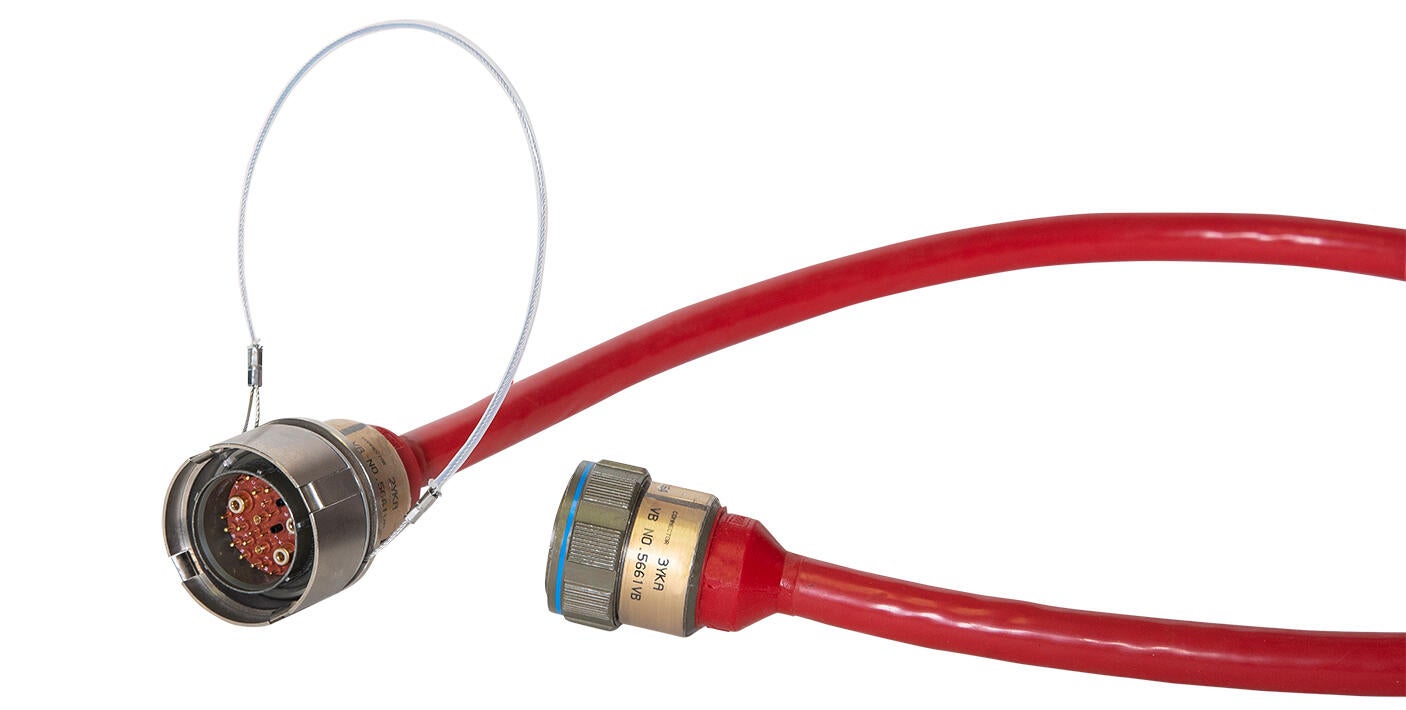

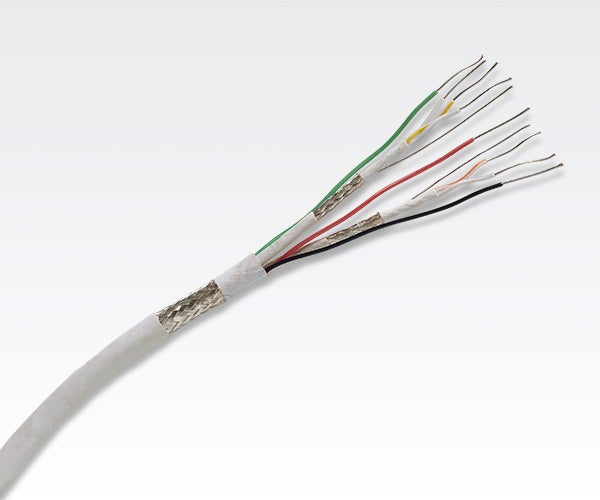

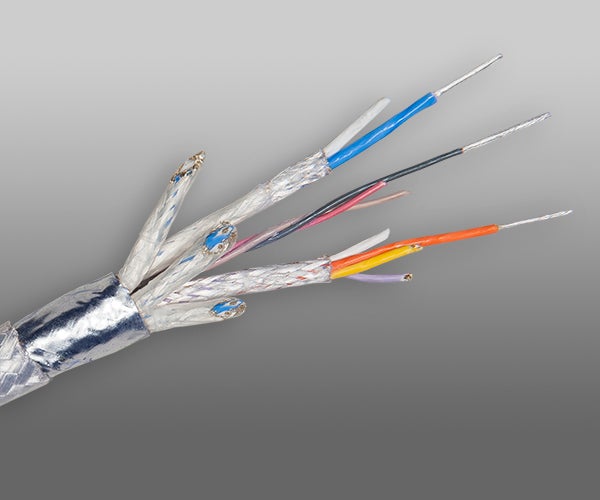

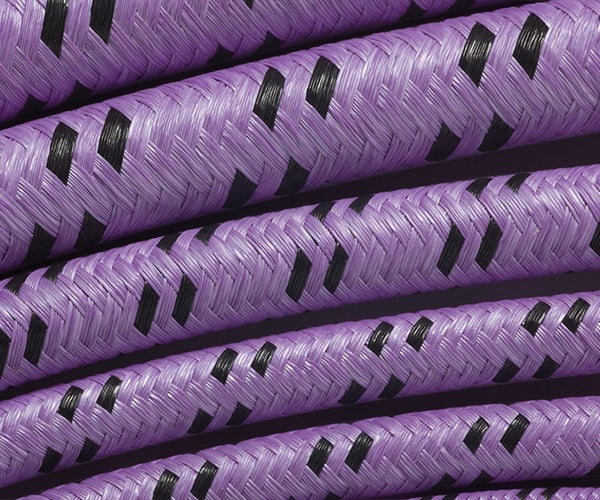

Le câble sert à acheminer l'alimentation électrique des systèmes électroniques et à envoyer des informations en temps réel à nos soldats, quelles que soient les conditions terrestres. La durabilité du câble est un facteur crucial. Gore fabrique donc une large gamme de solutions à petite échelle en fibre et en cuivre qui offre une protection blindée tout en délivrant des performances électriques stables. Réchauffement extrême jusqu'à 200 °C, températures arctiques jusqu'à -65 °C, sols boueux, routage complexe sont quelques exemples de facteurs qui ne pourront pénétrer, érafler ou couper les matériaux uniques que nous avons développés.

Cette durabilité sans équivalent associée à un acheminement rapide et durable de l'énergie et des signaux explique pourquoi l'armée continue à faire confiance à nos produits pour maintenir une communication sûre sur le terrain.

Systèmes terrestres

Test et mesure

Les systèmes électroniques, comme ceux que l'on retrouve dans les avions et les tours de téléphonie cellulaire 5G, doivent être scrupuleusement testés et mesurés afin de garantir leur performance pendant leur utilisation. La qualité du signal de l'équipement et la précision de mesure peuvent être mis à mal par les déplacements, le pliage ou les connexions des assemblages de test. Les performance ne peuvent pas être fiables si les tests ne le sont pas.

Gore propose une large gamme d'assemblages d'essai RF/micro-ondes extrêmement flexibles qui permettent d'effectuer des mesures précises et reproductibles avec une amplitude et une phase plus stables du continu à 110 GHz. Nos assemblages robustes avec diverses options de connexion solides ont montré qu'ils délivrent des performances fiables immédiates et durables. Ils réduisent les durées d'immobilisation et les frais liés aux essais en laboratoire, en cours de production, et sur le terrain. Enfin, et c'est le plus important, nos assemblages connectés à vos équipements garantissent des résultats toujours fiables !

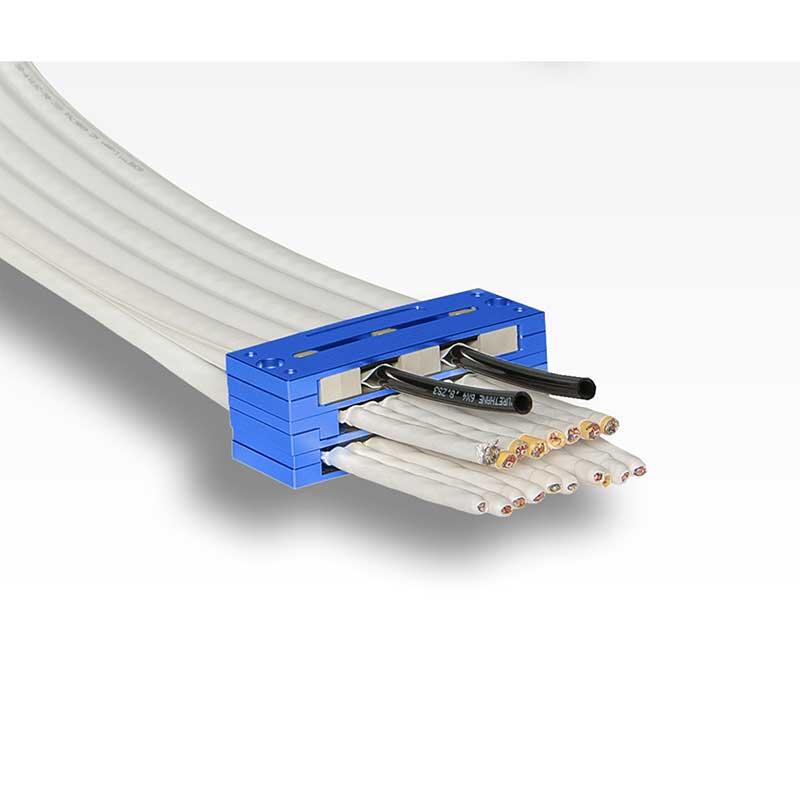

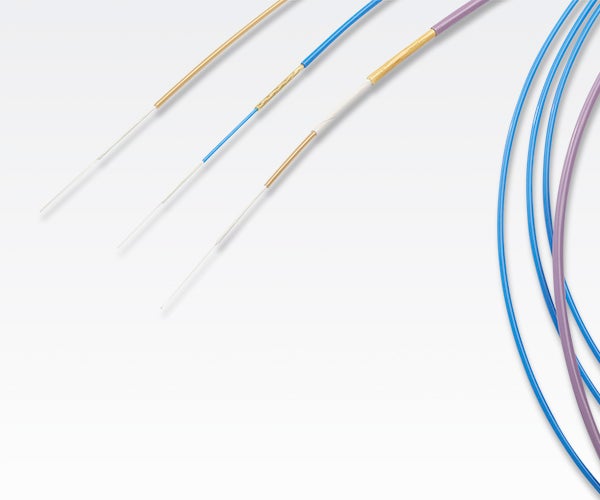

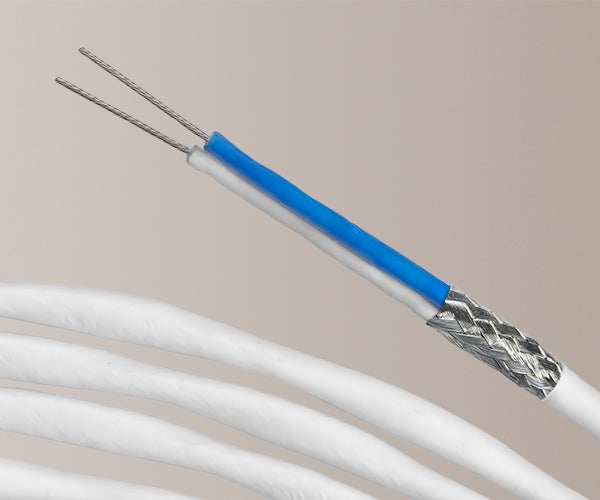

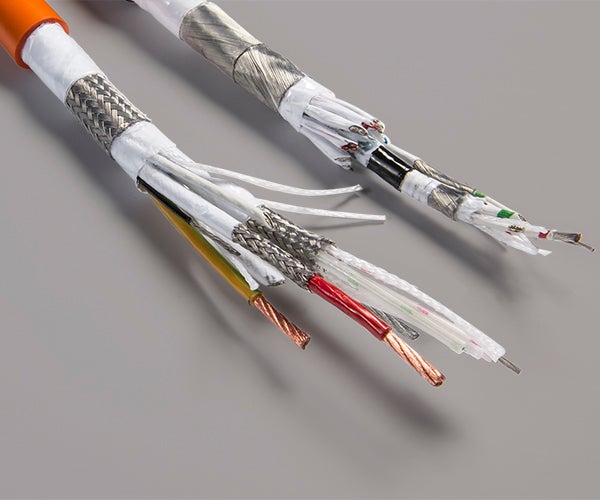

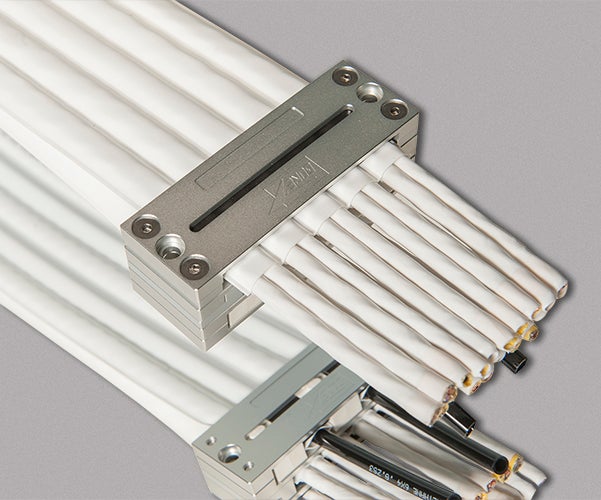

Automatisation industrielle / environnements difficiles

Du forage des puits de pétrole et de gaz au traitement des ressources naturelles, en passant par l'exploration marine géophysique et les salles blanches, les produits Gore ont été conçus spécialement pour résister à des environnements extrêmes tout en répondant aux exigences et réglementations industrielles les plus strictes. Quel que soit l'environnement (pression et température élevées, flexion continue, eau profonde), nous fournissons des solutions durables au fonctionnement précis, fiable et efficace tout au long de la durée de vie du système. Nos produits aident les fabricants à optimiser leur processus et à améliorer la fiabilité de leurs outils et équipements pour réduire les pannes et les retards coûteux.

Du forage des puits de pétrole et de gaz au traitement des ressources naturelles, en passant par l'exploration marine géophysique et les salles blanches, les produits Gore ont été conçus spécialement pour résister à des environnements extrêmes tout en répondant aux exigences et réglementations industrielles les plus strictes. Quel que soit l'environnement (pression et température élevées, flexion continue, eau profonde), nous fournissons des solutions durables au fonctionnement précis, fiable et efficace tout au long de la durée de vie du système. Nos produits aident les fabricants à optimiser leur processus et à améliorer la fiabilité de leurs outils et équipements pour réduire les pannes et les retards coûteux.

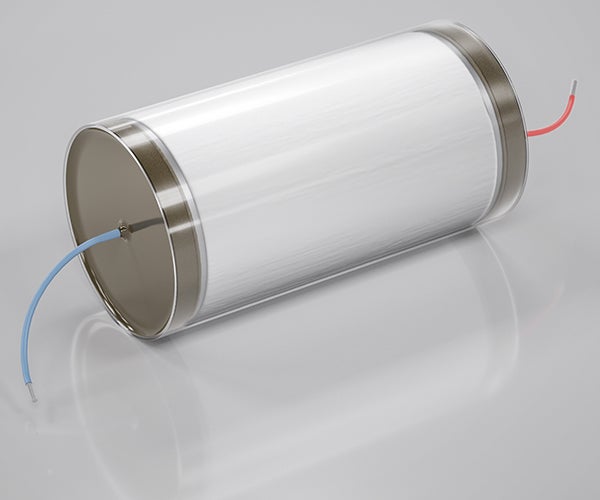

Nous continuons à associer notre expertise industrielle avec nos compétences techniques pour développer des produits de pointe, comme nos condensateurs haute température GORE™ High Temperature Capacitors primés pour l'électronique de puissance des outils de forage des puits de pétrole et de gaz, et les câbles souples GORE® Trackless High Flex Cables pour les systèmes de câbles mobiles en salle blanche.

Automatisation industrielle / environnements difficiles

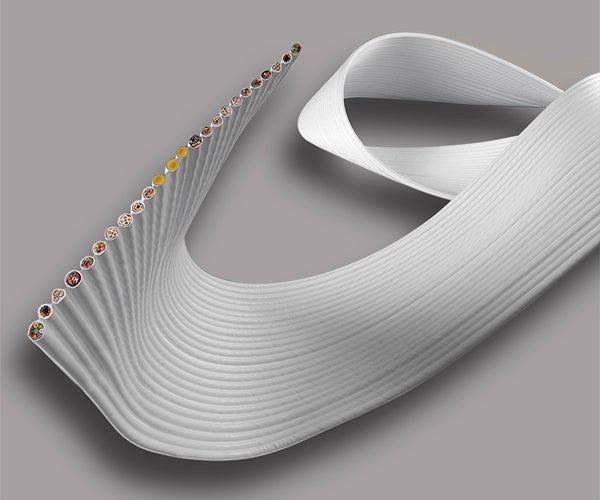

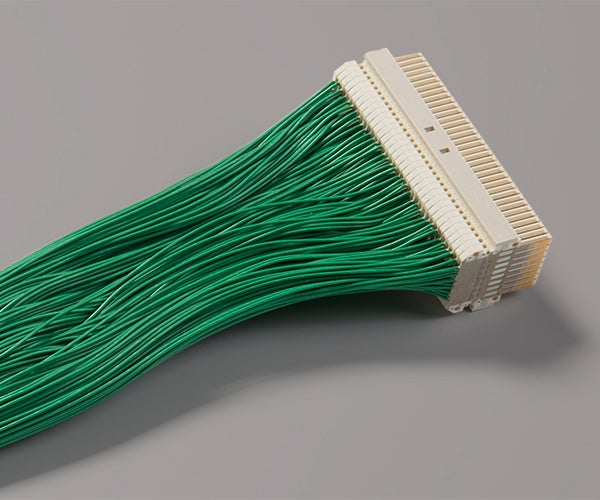

Informatique / réseau

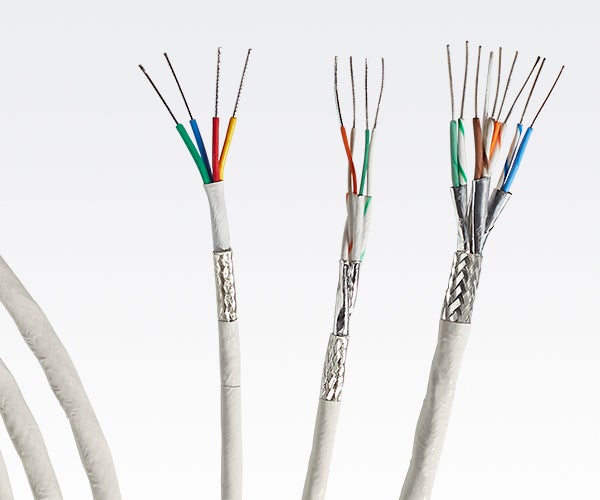

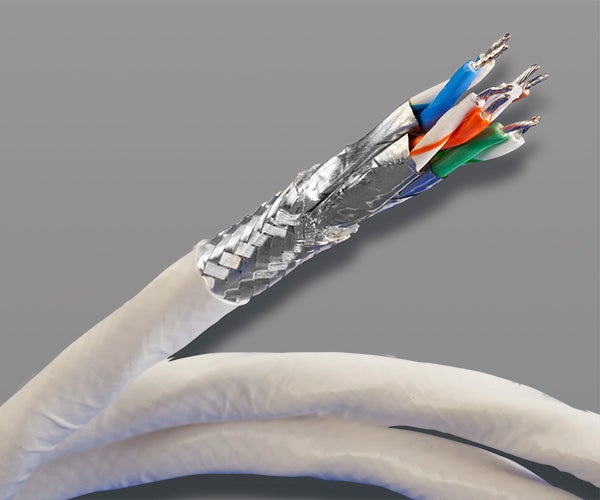

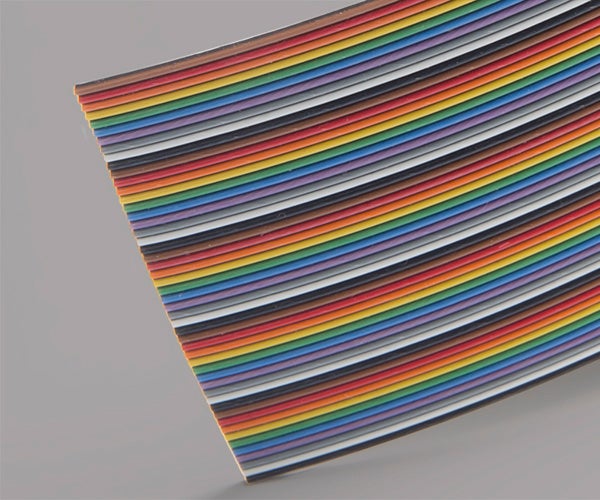

Gore répond aux besoins croissants de l'industrie en matière de câbles sur mesure haut débit pour les environnements informatiques, les réseaux et les laboratoires. Compacts, mais durables, nos câbles haut débit twinax délivrent des performances électriques et mécaniques exceptionnelles, même dans les applications soumises à des températures extrêmes.

Suivre Câbles et câbles assemblés